Cut Costs. Improve Quality. Zero Risk

REDUx Engineering’s Proprietary Cost-Reduction Process Combines Multiple Design For Manufacture Engineering Inputs with Pre-Vetted Managed Offshore Manufacturing in Tariff-Free Zones to Deliver 20%–50% Savings on Your Parts & Subassemblies – Without Upfront Costs or Consulting Fees.

DFM Engineering + Managed Offshoring = COGS SAVINGS

Manufacturing everything in-house? Outsourcing locally?

Either way, you’re paying too much while tying up capital, HR, and resources on non-core functions.

REDUxEngineering helps manufacturers cut costs by 20%–50% on non-core subassemblies – without compromising quality or taking on risk.

1. Exclusive Cost-Reduction Framework

Engineering-driven savings beyond traditional sourcing.

2. No-Risk, Contingency-Based Model

If we don’t deliver savings, you pay nothing.

- 3. World-class Engineering support On-demand experts in

- DFM

- material science

- Design for Logistics (DFL)

- and

- quality Design for Inspection (DFI)

4. Faster Time to Market

Early problem-solving prevents costly redesigns, speeding up development and production cycles.

5. Pre-vetted global suppliers

Long-term relationships with known outcomes: sourcing, audits, logistics, and compliance in multiple low-cost markets.

6. End-to-End Execution

From engineering inputs to offshore production, we handle it all.

OUR PARTNER CERTIFICATIONS

About Our Company

REDUx Engineering’s Proprietary Cost-Reduction Process Delivers 20%–50% Savings on Your Parts & Subassemblies—Without Upfront Costs.

REDUx Engineering’s Proprietary Cost-Reduction Process Delivers 20%–50% Savings on Your Parts & Subassemblies—Without Upfront Costs.

Manufacturing everything in-house? Outsourcing locally? Either way, you’re paying too much while tying up capital, HR, and resources on non-core parts.

REDUxEngineering helps manufacturers cut costs by 20%–50% on non-core subassemblies – without compromising quality or taking on risk.

- Exclusive Cost-Reduction Framework – Engineering-driven savings beyond traditional sourcing.

- No-Risk, Contingency-Based Model – If we don’t deliver savings, you pay nothing.

- World-class engineering support— On-demand experts in DFM, material science, Design for Logistics (DFL), and quality (Design for Inspection DFI).

- Pre-vetted global suppliers— Long-term relationships with known outcomes: sourcing, audits, logistics, and compliance in multiple low-cost markets.

- End-to-End Execution – From engineering inputs to offshore production, we handle it all.

About Our Company

REDUx Engineering’s Proprietary Cost-Reduction Process Delivers 20%–50% Savings on Your Parts & Subassemblies—Without Upfront Costs.

Manufacturing everything in-house? Outsourcing locally? Either way, you’re paying too much while tying up capital, HR, and resources on non-core parts.

REDUxEngineering helps manufacturers cut costs by 20%–50% on non-core subassemblies – without compromising quality or taking on risk.

- Exclusive Cost-Reduction Framework – Engineering-driven savings beyond traditional sourcing.

- No-Risk, Contingency-Based Model – If we don’t deliver savings, you pay nothing.

- World-class engineering support— On-demand experts in DFM, material science, Design for Logistics (DFL), and quality (Design for Inspection DFI).

- Pre-vetted global suppliers— Long-term relationships with known outcomes: sourcing, audits, logistics, and compliance in multiple low-cost markets.

- End-to-End Execution – From engineering inputs to offshore production, we handle it all.

HOW IT WORKS

Why REDUx? Because Our Process Works.

The REDUx Advantage – Built on Real Engineering, Not Guesswork.

01.

Performance-Based Model

No fees, no risk. We earn only when you save.

No fees, no risk. We earn only when you save.

02.

Engineering-Driven, Not Sourcing-Driven

Proprietary optimization beyond vendor quotes.

Proprietary optimization beyond vendor quotes.

03.

Exclusive Global Supplier Network

Pre-vetted partners in multiple low-cost markets with proven quality.

Pre-vetted partners in multiple low-cost markets with proven quality.

04.

On-Site Audits Before Shipping

Your parts meet spec before they leave the factory.

Your parts meet spec before they leave the factory.

How It Works

Unlike traditional sourcing firms that rely on quotes, we re-engineer costs from the inside out.

We analyse your subassemblies

Free assessment. No risk, no obligation.

01

We engineer cost savings

Optimized design, materials, manufacturing methods, packaging and logistics.

02

We execute with our vetted partners

Guaranteed quality with on-site audits.

03

Shipping-Optimized Logistics

Engineered for efficient packaging and transport.

04

You save—instantly

80% of the savings go directly to your bottom line.

05

No upfront fees. No consulting costs. We only win when you save.

Why REDUx? Because Our Process Works.

The REDUx Advantage – Built on Real Engineering, Not Guesswork.

Performance-Based Model – No fees, no risk. We earn only when you save.

Performance-Based Model – No fees, no risk. We earn only when you save.

Performance-Based Model – No fees, no risk. We earn only when you save.

Performance-Based Model – No fees, no risk. We earn only when you save.

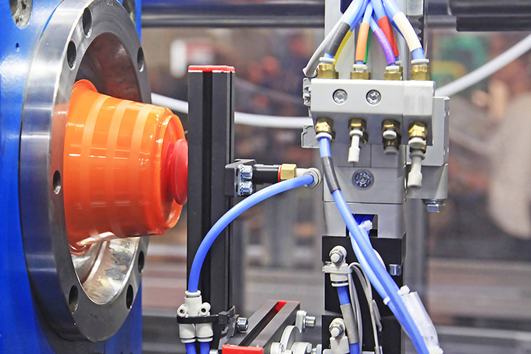

Our Case Studies

Showcasing real-world examples of how our solutions have delivered measurable success, highlighting key challenges, strategies, and impactful results.

Example of Successful Project CNC Machining Part

- Annual Volume:: 15,000 pcs/unit

- Original Cost: $12 each

- Project Time:: 3 months

- New Cost: $5 each

- Saving: $7 each

- Annual Saving: $105,000

Example of Successful Project Injection Molded Part

- Annual Volume: 8,000 pcs

- Original Material: Aluminum Casting + Machining

- Original Cost: $240 each

- Project Time: 5 months

- New Material: Mixed composite for injection molding

- Mold cost: $60,000 (one time)

- New Cost: $52 each

- Saving: $188 each

- Annual Saving: $1,504,000

Example of Successful Project Structural Reactive Injection Molding Part

- Annual Volume: 7,500 pcs

- Original Material: CNC machining parts + assembly

- Original Cost: $574 each

- Project Time: 6 months

- New Material: Mixed composite for injection molding

- Mold Cost: $85,000 (one time)

- New Cost: $287 each

- Saving: $287 each

- Annual Saving: $2,152,000

Example of Successful Project Chopped Spray Fiberglass Part

- Annual Volume: 5000 pcs

- Original Cost: $82 each

- Project Time: 1.5 months

- Mold Cost: $3,000 (one time)

- New Cost: $18 each

- Saving: $64 each

- Annual Saving: $320,000

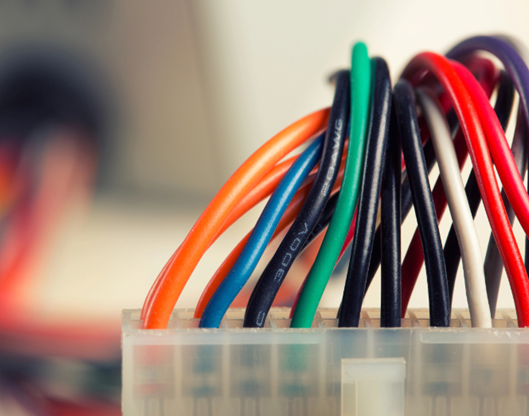

Example of Successful Project Submersible Cable Assembly

- Annual Volume: 7500 pcs

- Original Cost: $74

- Project Time: 3 months

- Mold Cost: $8000 (one time)

- New Cost: $32

- Saving: $42 each

- Annual Saving: $315,000

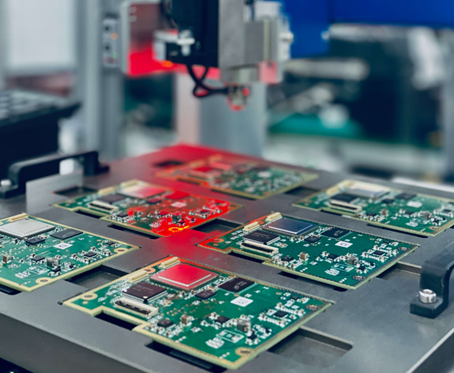

Example of Successful Project PCBAs

- Annual Volume: 80,000 pcs

- Original Cost: $85

- Project Time: 4 months

- New Cost: $65

- Saving: $20 each

- Annual Saving: $1,600,000

Example of Successful Project Signal Control Cable

- Annual Volume: 1,000,000m

- Original Cost: $2.20 per meter

- Project Time: 4 months

- New Cost: $0.90 per meter

- Saving: $1.30 per meter

- Annual Saving: $1,300,000

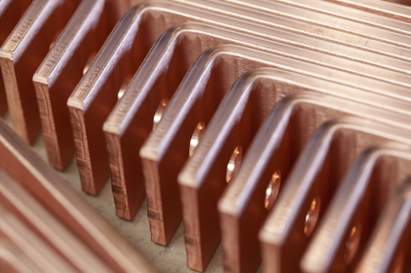

Example of Successful Project Rigid & Flexible Busbars - Power cable assemblies and internal CNC-bent busbars

- Technical requirement: 1000VDC/750A continuous. Salty water. -40C to +65C operating temperature. 50G shockwave.

- Annual Volume: 10,000 pcs

- Original Cost: $300

- Project Time: 6 months

- New Cost: $100

- Saving: $200 each

- Annual Saving: $2,000,000

The Result? Better Parts at a Lower Cost—Guaranteed.

Unlike brokers or consultants, we don’t just introduce suppliers—we engineer the cost savings from the ground up.

Let’s Cut Your Costs—Without the Risk.

Our proprietary process delivers guaranteed savings. Are you ready?